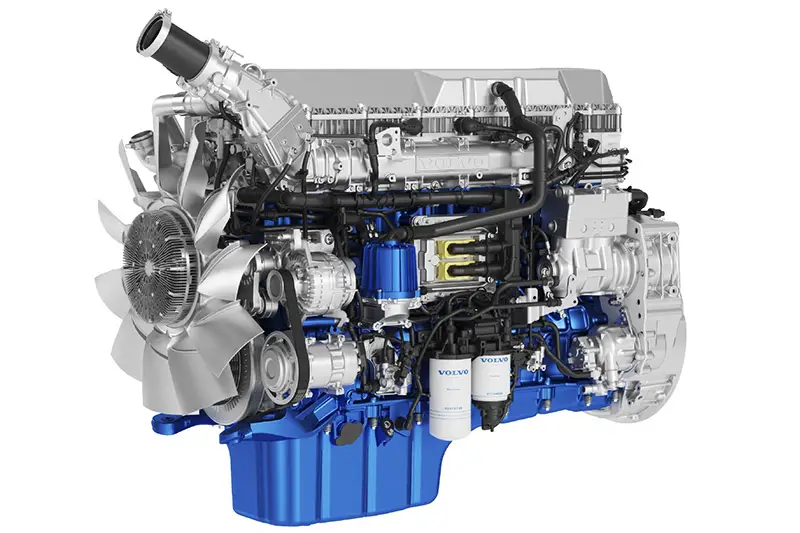

Volvo trucks are well known for their high-performance and efficient engines. They also have engines that are suited for a wide range of applications.

However, Volvo truck engines may experience some trouble after putting some mileage on them. This is often due to worn-out components or sometimes a lack of TLC.

If you want to avoid any conveniences when driving your rig, here are the common problems you may face with your Volvo truck engine and some tips on how to fix them.

A Short Summary of Common Volvo Truck Engine Problems to Expect:

Typical Volvo truck engine problems are vibration at idle, engine overheating, malfunctioning turbo, blown head gasket, and truck losing coolant. These issues will negatively impact the performance of your Volvo truck and may result in further engine damage if not resolved urgently.

Table of Contents

Volvo Truck Idle Problem

Turning idle will help your Volvo truck engine keep running even if the truck itself is not moving.

Most drivers also use idling to know if their truck is still in its top shape. Thus, if you encounter rough idling, it may mean several issues with your truck’s engine.

The first thing you will notice if your truck has an idle problem is that you will feel like it is shaking or bouncing. You might also hear odd sounds or smell weird odors.

Here are the problems you may encounter relating to rough idling:

Volvo Truck RPM Problem

Revolutions per minute or RPM measures how fast the machine operates at a given time.

On average, a truck has 600 to 1000 RPM. If your engine has idle problems, you will see sudden changes and exceed the average RPM.

When you encounter this problem, clean the MAF sensor from dirt first.

One of the results of a grimy MAF sensor is rough idle and will also cause the RPM to act weird. You can also inspect the throttle body if it also needs cleaning.

After following the previous solutions, you can check the IAC valves if the problem persists. If it is clogged, you can remove it for further cleaning as it also causes the RPM to malfunction.

While doing all the above methods, you can also try checking the air filter for possible broken vacuum lines and replace them.

Volvo Truck Vibration at Idle

Vibration at idle is a common occurrence on trucks. But if you often experience it, you need to know the exact cause for safe driving and maintaining your truck’s performance.

One of the problems you may experience is broken spark plugs. Over time, spark plugs wear out and get dirty.

If left unclean or replaced with a new one, it can misfire, causing the engine to vibrate at idle.

A dirty fuel intake system can also cause a misfire to your truck’s engine resulting in vibration or shaking.

Always check and clean your truck’s intake system and the fuel pump to avoid this issue.

Loose or worn-out engine belts can cause vibration and produce a squealing sound. You need to adjust or replace it to prevent vibration when your truck is idle.

Another cause of vibration at idle is broken hoses. The hoses on your truck’s engine get worn out as time passes. Replace any of them right away to prevent other problems.

Volvo Truck High Idle

When your truck’s idle, especially when waiting for the green light, you may notice it increases speed as soon as you resume driving.

High idle in trucks can result in fuel waste and wear and tear down the engine. Most of the time, the main perpetrators of high idle are bad fuses, faulty computer systems, and leaks on the IAC’s port.

- Bad fuses

The IAC controls the engine’s idle speed. Thus, if there are any terrible fuses on the IAC motor, it can affect the idle speed. Check it right away and replace necessary fuses as needed.

- Faulty Computer System

A faulty computer system can also be the culprit of high idle. Since the computer control system of your truck could not read the correct idle speed, it changes more often, resulting in a high idle.

Another problem you need to check is when your truck’s throttle malfunctions. It can cause sudden changes in your truck’s idle speed and create dirt buildup and cracks on the air intake tube.

- Leak

Lastly, when there is a leak on the IAC’s vacuum port, it can also cause a high idle. The leak often comes from the seal of the attached hoses on the IAC.

Thus, conduct regular checkups, so it will not cause severe issues with your truck’s engine.

Aside from all these, engine overheating and a bad alternator also cause high idle. You should often check on these parts to maintain safety when driving.

Volvo Truck Turbo Problems

Turbo failures are also a common issue among Volvo trucks.

The biggest problem you may encounter is the bearings and seals, intake supporting parts, exhaust supporting parts, charge pipes, and the control parts of your truck’s turbo.

The turbo is such a delicate and sensitive mechanical part of every vehicle.

Thus, diagnosing possible issues or problems with it will help you prolong your truck’s lifespan and ensure safe driving. But how will you know if your truck’s turbo is already failing, and how can you fix it?

Volvo Truck Bad Turbo Symptoms

There are three symptoms you can note to determine a bad turbo.

1. Louder noises coming out from the engine than usual.

2. An increasing amount of exhaust comes out from the tailpipe. If you fail to oil the turbocharger properly, it will spin faster than its normal motion, which results in more exhaust gasses.

3. Decrease fuel economy and power because of deteriorating performance from the exhaust gas recirculation system.

With proper diagnosis, you can avoid severe damage to your Volvo truck’s turbo as soon as you encounter any or all of these symptoms.

Volvo Truck Boost Pressure Sensor Problems

The boost pressure sensor works by ensuring that the turbocharger does not blow and overload the engine.

If your truck has boost pressure sensor problems, you will see a check engine light on your truck’s dashboard.

You may also notice sudden changes in the speed of your vehicle every time you try to accelerate and abnormalities in the engine’s performance.

Once you encounter an issue with the boost pressure sensor, you must fix it immediately. You cannot continue driving with this kind of problem in your truck since it can cause serious accidents.

The best solution is to replace the sensor to save yourself from the more expensive repair costs. If neglected, this can cause overheating in the engine, affecting other vital parts of your truck.

Volvo Truck Low Boost Pressure

The turbo engine of your Volvo truck increases its overall performance, providing you with a smooth drive.

However, it may also malfunction and give you an inefficient driving experience.

If your truck has a restricted exhaust, it will result in low boost pressure.

The engine will need more force to push the exhaust. Therefore, it lowers the energy it transmits to the engine as you drive.

Other causes of low boost pressure are lack of oil supply, oil leakage, and air leakage.

Here are basic troubleshoots you can try to fix low boost pressure in your Volvo truck:

1. You can first try to increase the boost pressure. There are two ways to do it:

- Reducing the rod’s length to increase the preload. You will notice it will have a maximum boost to open the wastegate valve.

- Bypassing the turbo by removing the pin and disassembling the valve and the spring mechanism.

2. Observe the vacuum or the boost indicator light. It may need a more severe repair if it still shows significantly low pressure.

If you fail to recognize these issues, it can cause long-term problems with your truck. Worse, it may not be fixed at all.

Volvo Truck Coolant Problems

The coolant system keeps the temperature of the truck’s engine at an optimal level. It also allows other components of your vehicle to stay cool.

The most common problems you may encounter with your Volvo truck’s coolant are overheating temperature irregularities and faulty blown head gasket.

The coolant breaks down over time. The best remedy is to replace it with a new one since it cannot return to its previous property and condition once it gets damaged.

Volvo Truck Overheating

Coolant leakage, clogged hose, broken water pump, and faulty radiator fan often cause overheating to the engine and other truck parts.

If you see steam coming out of the truck’s hood, sniff a burning smell, and notice a red sign on the temperature gauge on the dashboard, your truck is probably overheating.

To fix the issue, follow this guide.

- Slow down, pull over the truck on the roadside or at a safe location, and turn the engine off.

- Please wait a few minutes or until the steam stops coming out of the engine before you open the hood to check its condition.

- If you have a coolant, try to add it to prevent overheating, especially if leakage is the culprit.

- You may contact roadside assistance for towing service. You can also restart the engine and drive to the nearest repair shop.

Volvo Truck High Coolant Temperature

You may often experience high coolant temperature because of a faulty coolant system and a clogged radiator due to dirt and rust.

To fix it, wash the radiator to remove any particles restricting the airflow. Remove the radiator first to split it apart and clean it easily.

Volvo Truck Losing Coolant

A hole in the radiator, issues with the water pump, cracked hose, and leakage on the coolant all contribute to lowering the coolant level of your truck.

Once you notice this issue, check for any leakage in the coolant system. However, there are also cases when leakage is not the primary source.

Thus, inspecting the reservoir cap and the head gasket will also help ensure that the coolant temperature maintains its optimal level.

Volvo Truck Blown Head Gasket Symptoms

The blown head gasket plays a vital role in keeping the coolant and oil separated in the engine.

You can tell if your truck has a faulty blown head gasket by frequently overheating the engine, mixing coolant and oil, and engine start failure.

You can diagnose it by conducting a coolant pressure or cylinder compression test. You can do these tests yourself or consult your mechanic for a more thorough checkup and repair.