Synchronized transmissions are commonly found in cars. They came about as early as 1928. However, they weren’t found in every car until much later.

A synchro is built into the transmission to help match the engine speed to the speed required for the next gear.

This makes gear changes much easier, smoother, and faster. Without a synchronized transmission you would need to use a double-clutch or rev-matching technique with every gear change to match the engine and gearbox speeds.

Here’s a quick answer to whether Semi Trucks have Synchronized Transmissions:

Synchronized transmissions are not commonly found in semi-trucks in the U.S. However, they are more common in European trucks. These transmissions can be unreliable and expensive to maintain. However, they make driving the truck much easier. In future we may find these transmissions used more often.

Table of Contents

Do Semi-Truck Transmissions have Synchros?

Many semi-trucks do not have synchronized transmissions. There are a couple of reasons for this decision.

The first is that semi-trucks need heavy-duty transmissions. This means that the parts required to build them are much larger and heavier than those used in building transmissions for cars.

In addition, semi-truck gearboxes have more gears than car transmissions. The average semi-truck has a 10-speed gearbox, and some have even more gears.

This means that the transmission found in a semi-truck is not only larger and heavier, but it also has more moving parts than one found in your average car.

Synchros add several extra moving parts. This means there is more potential for breakages and reliability issues within the gearbox.

Building a synchronized gearbox for semi-trucks would also be much larger and make for more awkward positioning on the vehicle.

However, some of the latest semi-trucks do have synchronized transmissions. Modern technology has allowed them to create synchronized transmissions.

Many modern semi-trucks now also have automatic transmissions. This is more commonly found in Europe than the United States though.

How do Synchronized Gears work in Semi-Truck Transmissions?

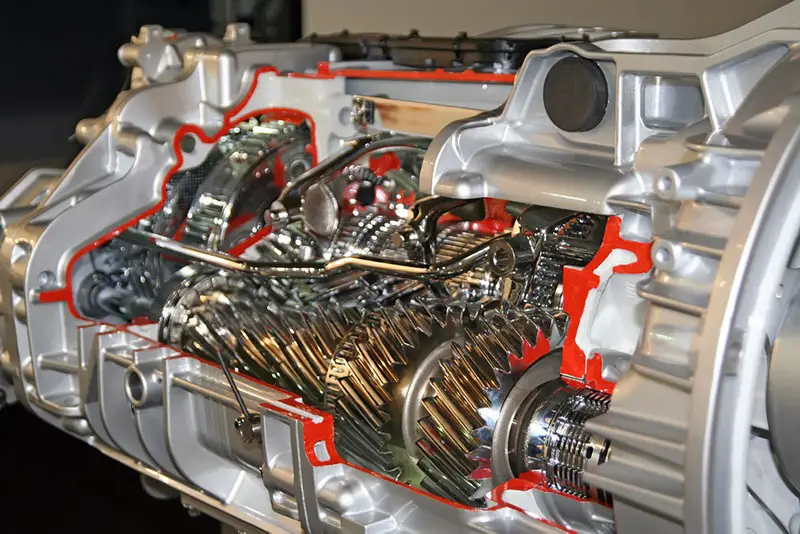

Synchronized transmissions are complex. They have many extra moving parts compared to unsynchronized transmissions.

This is because a synchro has an incredibly important job to do. It needs to match the speed of the engine with the speed required for the next gear.

This allows the gear change to be as smooth as possible by allowing the next gear to be ready to be activated. The process behind this is complex and intricate.

However, a synchro needs to constantly ‘mesh’ idling gears with the one that is active. To do so, it requires a more complicated system.

The result of a synchro transmission is much faster and smoother gear changes, making the truck easier to drive.

How do you Drive a Semi-Truck Without Synchros?

Semi-trucks without synchronized transmissions are extremely difficult to drive. Without the system that matches the engine speed correctly to the next gear, the driver needs to take over this process.

The driver needs to make use of specialized driving techniques when driving a truck without synchronized transmissions. This takes some skill and practice.

The main technique that a driver will be using is double clutching. This technique is used to manually ‘sync’ the gears.

It involves clutching twice during one shift. For example, the clutch pedal will be pressed down, and the transmission will be put into neutral. The clutch pedal will then be released.

This allows the gearbox to neutralize the speed of the drive shaft. The clutch will be pressed down again, and the transmission will be shifted into the next gear before the clutch is released again.

This technique, however, is extremely tiring for drivers. The clutch found in a semi-truck is heavy-duty means that the clutch pedal is extremely difficult to press down.

Rev matching is another technique that can be used by drivers. This involves pressing down on the clutch pedal and keeping the clutch disengaged while shifting gear.

Just before releasing the pedal to reengage the clutch, the driver will rev to the engine to bring the speed up and match the speed required for the next gear.

Is it Easy to drive a Semi-Truck Without Synchronized Gears?

Driving a semi-truck is no easy job at all. Due to the heavy nature of the vehicle, everything requires more strength and concentration to operate properly.

However, a truck with a synchronized gearbox will be significantly easier to drive. While it won’t change the stiffness of the clutch pedal, it does mean that specialized driving skills will not be required.

The advantage to this is that the driver will be able to focus more on the road and observing their surroundings.

Which Semi-Trucks have Synchronized Gears and Which Don’t?

As technology improves in our modern society, synchronized transmissions are found in semi-trucks more regularly.

However, synchronized transmissions are mostly found in European semi-trucks. Volvo is one example of a manufacturer that uses synchronized transmissions in their trucks.

Semi-trucks found in the United States have unsynchronized transmissions more often than not. Though this fact is changing.

As technology develops, more and more companies are beginning to invest in trucks that have synchronized transmissions.

This is mainly because of safety. Taking pressure off the driver by reducing their workload allows them to drive farther and for longer amounts of time.

It also allows them to focus more on the road. Synchro transmissions are being built into semi-trucks because of how much they have developed.

They are no longer as unreliable as they used to be. It is also significantly cheaper and easier to repair and maintain.

Which Semi-Trucks have the Best Synchronized Transmissions?

Synchronized transmissions are not used by many semi-trucks. As such, the best synchronized transmissions can be found in Volvo trucks.

Technology is constantly improving though, and soon we will see great synchronized transmissions in all modern trucks.

We can expect the next generation of semi-trucks to be fully equipped with the latest technology, and we will begin to see unsynchronized transmissions becoming a thing of the past.

How many miles do Semi-Truck Synchros Last?

Generally, synchros in transmissions can last longer depending on the driving style of the driver. If a driver is smooth on gear changes and with general driving, synchros can last up to 60,000 miles in a semi-truck.

However, if a driver is aggressive in their driving style, with quick gear changes, hard braking and fast acceleration, the synchros in transmission can take some strain.

Being a delicate and complicated system, synchros can easily be damaged through incorrect use of the transmission. They could become damaged after just 10,000 miles in some cases.

How to know if your Semi-truck has a Bad Synchro?

Bad synchros will make your semi-truck nearly undrivable. There are several signs you need to look out for if you think your semi-truck has bad synchros in the transmission.

The first is griding gears. Every now and then, some drivers do grind gears by releasing the clutch too early or not pushing the pedal down enough. However, if you find that your semi-truck is grinding its gears regularly despite proper clutch use, you might have bad synchros.

Another tell-tale sign of bad synchros is if the transmission pops out of gear, or if it struggles to go into gear. If this happens regularly, you need to take your transmission in for maintenance.

Can you Fix Bad Synchros in a Semi-Truck?

It is possible to fix bad synchros in your transmission. However, due to the complexity of the system, it is highly recommended to take your semi-truck to a transmission expert who will know how to fix the problems.

This could be as simple as refilling the fluids in the transmission. Transmission fluids deplete with usage, so it is completely normal for replenishment to be needed after some time.

Another possible solution the transmission expert may use is to clean the transmission. They will do this by using cleaning chemicals and techniques.

What are the Benefits of Semi-Trucks with Synchronized Transmissions?

There are some benefits to having a synchronized gearbox in your semi-truck. They can be extremely useful.

Firstly, the semi-truck will be significantly easier to drive. This is because the synchronized transmission allows for smoother and easier gear changes.

As a result, there will be less of a workload on the driver. Thus, fewer drivers need to stop and rest out of exhaustion.

Having easier gear changes will also allow the driver to focus more on the road and their surroundings. This will result in fewer accidents for semi-trucks.

What are the Pitfalls of Semi-Trucks with Synchronized Transmissions?

Despite the benefits of synchronized transmissions, there are also some disadvantages to having them.

The first is that they are expensive to build and maintain. This is due to the complexity of the system. Maintenance needs to be done by a transmission expert.

Another disadvantage is that these systems have more moving parts than unsynchronized transmission. This means there are more parts that can fail, resulting in poorer reliability.