A bull gear is a major player in keeping the engine running smoothly. We will take you through how they work, where they are located, and how much they cost to replace.

We also talk about their maintenance, typical issues they may have, how to prolong the life, and if all semi trucks have them.

Here’s a Quick Answer to what is a Bull Gear on a Semi Truck:

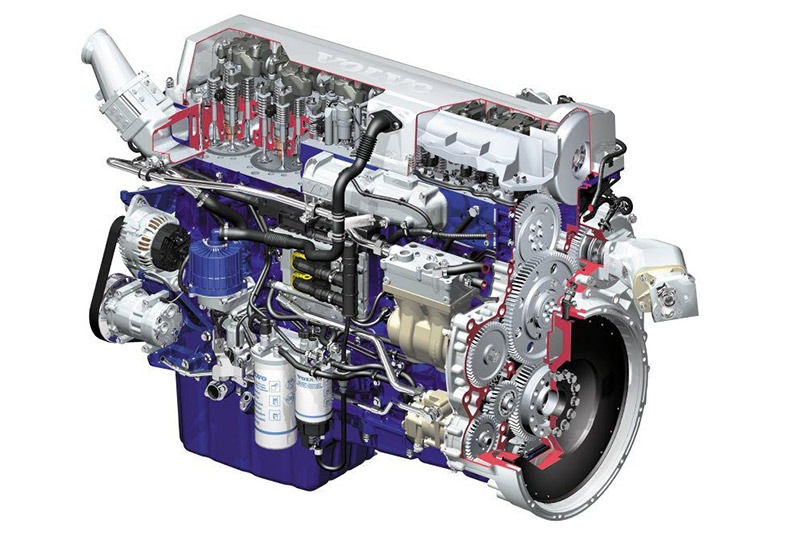

A bull gear is an integral part of a semi truck engine’s gear train. Depending on the engine design, a bull gear drives all gear-driven engine accessories such as the compressor, fuel pump, water pump, power steering pump, and alternator. The bull gear itself is driven by the crankshaft timing gear.

Table of Contents

What is a Bull Gear on a Semi Truck?

A bull gear is used as an output gear. Together with the pinion gear, it works to keep the engine running smoothly. Bull gear is an important part of a semi truck’s engine.

It is the largest gear in the truck and is surrounded by teeth that mesh with the connected components teeth to spin the inner engine components in a timely fashion.

It is important that the timing is right for the engine to work.

Do all Semi Trucks have Bull Gears?

Not all semi trucks have a bull gear. A few that do is the Detroit 60 series (12.7L and 14L), the Cummins ISX, and the Volvo D13 engines. The DD15, DD13, and DD16 do not have a bull gear.

Most semi trucks with a transmission composed of two toothed wheels that mesh together and involve spur gears will have a bull gear. Semi trucks with a manual transmission have a bull gear.

The bull gear is a major component in the gear system and will need to be well maintained.

It is a good idea to familiarize yourself with your truck’s inner features to help you understand what to look out for when looking at the engine.

Where is a Bull Gear on a Semi Truck Located?

The bull gear in a semi truck is located under the cam, above the crank, and between the engine and transmission. It is in the midsection. The transmission will need to be removed to access it.

Some trucks have the bull gear at the front of the engine, like the Detroit 60 series, while the Volvo D13 has it at the rear of the engine. The bull gear is driven by the crankshaft timing gear.

How do Bull Gears in a Semi Truck work?

The bull gear is a large idler gear in the center of the timing gears. It is connected to the camshaft, the accessory drive gear, the crank gear, which turns the bull gear.

The air compressor and the power steering are connected, and all run off the bull gear. The crank gear turns the bull gear, the bull gear then turns the rest of the connected components.

The bull gear needs to be checked for bearing play every year or if you hear unusual knocking noises. Sometimes the knocking noise will only occur when the air compressor is on.

What are the Typical Problems Associated with a Semi Truck Bull Gear?

If the bull gear in a semi truck goes wrong, it can cause issues with the oil pump that may suck up metal shavings, and gear bearings will also collect metal shavings.

When the retainer on bull gear works its way off through vibration and wear it allows the bull gear room for play. The bull gear will then have a slight wiggle to it.

It will cause it to rub against the inner housing and the other connecting components such as the air compressor and the idler gear. They will be subject to abnormal play.

It could, in turn, cause issues to other connecting components.

How to Tell if the Bull Gear on a Semi Truck is Bad?

A bull gear goes bad when a bit of play develops and the gear doesn’t run on its designed centre.

Typically, a bull gear develops play when its bearing fails or the retainer that holds the bull gear into position becomes loose and falls out.

This causes the excessive gear lash between the bull gear and other gears that it drives and results in wear of gear teeth and metal shavins that can makes its way in to the engine.

The most tell tale sign that a bull gear is bad is the sound that will be coming from the gear train. It will be very noisy, and the noise usually worsens when the engine speeds up.

The other way to check if the bull gear is bad is to check if there is any play of the bull gear. A good bull gear should not have any play att all once set correctly.

You can also check the condition of the other gears that it drives, e.g. the compressor gear. If the teeth of the compressor gear is damaged, this could be a sign of a bad bull gear.

What Maintenance is Done on a Semi Truck Bull Gear?

The teeth on a bull gear are loaded and stressed by sliding contact, causing surface fatigue damage. Bending and rolling contact will result in localized stresses and deformation.

It can cause breakage on the teeth. If the teeth break, it will cause metal shavings and debris to spread around the counterparts of the engine, resulting in complete engine failure.

To prevent this from happening, regular maintenance of the bull gear is essential. Make sure the gears are well lubricated. Check the oil level often and every year.

Loosen the alternator belt, carefully remove the auxiliary gear and housing. It has an O-ring that can break if you get too rough with it. Use a pry bar to check for play between the gears.

You can also check between the bull gear and housing for play. If there is play on the bull gear, or you notice damage to any of the teeth. Do not continue to drive the truck.

Unless it is to the nearest workshop, early detection of any bull gear issues will save you a ton of cash.

It is recommended to change the bull gear at a 750,000 mile interval.

We also recommend to check all other gears that are driven by the bull gear to have them inspected or replaced as the the cost of labour is significant, and it will save you money in the long run.

How to Prolong the Life of a Bull Gear on a Semi Truck?

To prolong the life of a bull gear in a semi truck. It is essential to use the manufacturer’s recommended oil. Cheap oil will damage your engine.

Regularly check for play between the gears with a pry bar. Listen for unusual noises the engine makes. The load the engine is subjected to will cause strain on the gears.

The temperature will rise along with that strain. It will put stress on the bull gear’s teeth. Using the correct thickness of oil will prolong the bull gear’s life.

Using the vehicle smoothly and correctly will also prolong the bull gear’s life as the engine components are linked somehow.

It is very important not only for the life of the bull gear but for the rest of the engine components.

Do not overload your truck and put unnecessary strain on the gears.

Never float your gears when driving. I know it is tempting to do this, as you drive many miles a day, but it is not good for the engine.

Floating will eventually cause issues with them as they are designed to be used with a clutch. Check for oil leaks around the entire timing gear area.

Do not ignore any leaks. Investigate them and have them seen as soon as possible.

What is the Cost of Replacing a Bull Gear on a Semi Truck?

The cost to replace a bull gear with a workshop will vary from shop to shop. The average price of the bull gear alone is from $1100 to $1500. The bearings will set you back around $80 to $90.

Taking labor into account, the total cost can be anywhere from $2500 to $20,000 plus, depending on the damage it has caused.

It can cause damage to the auxiliary gear, the oil pump, all the surrounding component’s bearings, and anything else that has been unfortunate enough to get in the path of the debris left behind.

If you are replacing the part yourself, you will no doubt save a lot of money. You could get away with having the bull gear reconditioned.

The recon can set you back around $800. The bull gear is strong alloy steel. It is very durable and can last over a million miles. You may never need to replace one.